Introduction:

In the vast landscape of engineering, machinery, and technology, Rubber O-Rings have silently emerged as essential components, diligently sealing and safeguarding the integrity of countless systems and applications. Revered for their precision, versatility, and longevity, these unassuming rings are the unsung heroes of modern engineering. This article embarks on an exploration to uncover the multifaceted world of Rubber O-Rings, revealing their unique attributes, practical advantages, and the diverse applications that have established them as indispensable to professionals and industries worldwide.

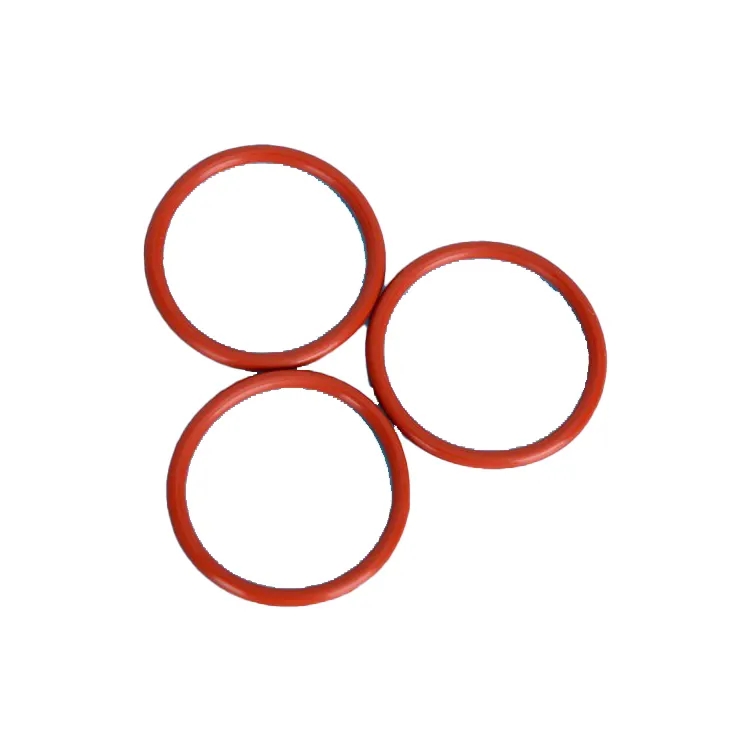

Rubber O-Rings: The Pioneers of Precision Sealing

Rubber O-Rings are circular elastomeric seals, typically made from high-quality rubber compounds, designed to fit snugly within the grooves of mating parts to create a watertight and airtight seal.

Advantages of Rubber O-Rings:

Versatility: Rubber O-Rings are available in various sizes, materials, and configurations, making them suitable for a wide range of applications, from hydraulic systems to household appliances.

Sealing Excellence: Their precision in creating a tight seal is unparalleled, preventing leaks and ensuring the integrity of systems in even the most demanding conditions.

Chemical Resistance: Rubber O-Rings can be manufactured from different rubber compounds, offering resistance to various chemicals, making them valuable in industries where exposure to corrosive substances is a concern.

Temperature Tolerance: These O-Rings can withstand a wide temperature range, ensuring their reliability in both extreme cold and heat.

Cost-Effective: Rubber O-Rings provide a cost-effective sealing solution, requiring minimal maintenance and replacement, thus reducing operational costs.

Customization: They can be custom-designed to fit unique profiles and sizes, offering a precise sealing solution for specific applications.

Shock Absorption: In addition to sealing, Rubber O-Rings also possess shock-absorbing properties, protecting delicate components from damage due to vibrations and impacts.

Applications of Rubber O-Rings:

Automotive Industry: Rubber O-Rings are widely used in engines, transmissions, and hydraulic systems to prevent fluid leaks and maintain optimal performance.

Hydraulic Systems: O-Rings play a crucial role in hydraulic equipment, ensuring the integrity of fluid transfer in construction machinery and industrial equipment.

Plumbing: They provide reliable seals in plumbing systems, preventing water leaks and ensuring a safe water supply in households and commercial buildings.

Medical Devices: Rubber O-Rings are used in medical equipment, where precision and biocompatibility are crucial, ensuring the safe and sterile functioning of devices.

Aerospace: In the aerospace industry, they are utilized in critical applications, such as fuel systems and engines, where reliability and precision are non-negotiable.

In Conclusion:

Rubber O-Rings, though often overlooked, are the pioneers of precision sealing, ensuring the integrity and reliability of countless systems and applications. Their unique attributes, including versatility, sealing excellence, and resistance to chemicals, make them the preferred choice for professionals and industries worldwide. Whether you’re addressing the challenges of automotive engineering, hydraulic systems, or household plumbing, Rubber O-Rings provide the precision and reliability needed to seal with confidence. Explore the world of Rubber O-Rings and experience their enduring performance, ensuring the success of your projects, regardless of their complexity or scale.