Introduction:

In the intricate world of engineering and manufacturing, the significance of Rubber O-Rings cannot be overstated. These small yet mighty components serve as the unsung heroes that ensure precision, efficiency, and reliability across a multitude of systems and applications. Celebrated for their sealing prowess, adaptability, and durability, Rubber O-Rings have quietly become the cornerstone of modern engineering. This article embarks on a journey to demystify the world of Rubber O-Rings, shedding light on their unique attributes, practical advantages, and the wide-ranging applications that have solidified their status as indispensable components for professionals and industries globally.

Rubber O-Rings: The Unsung Pioneers of Precision Sealing

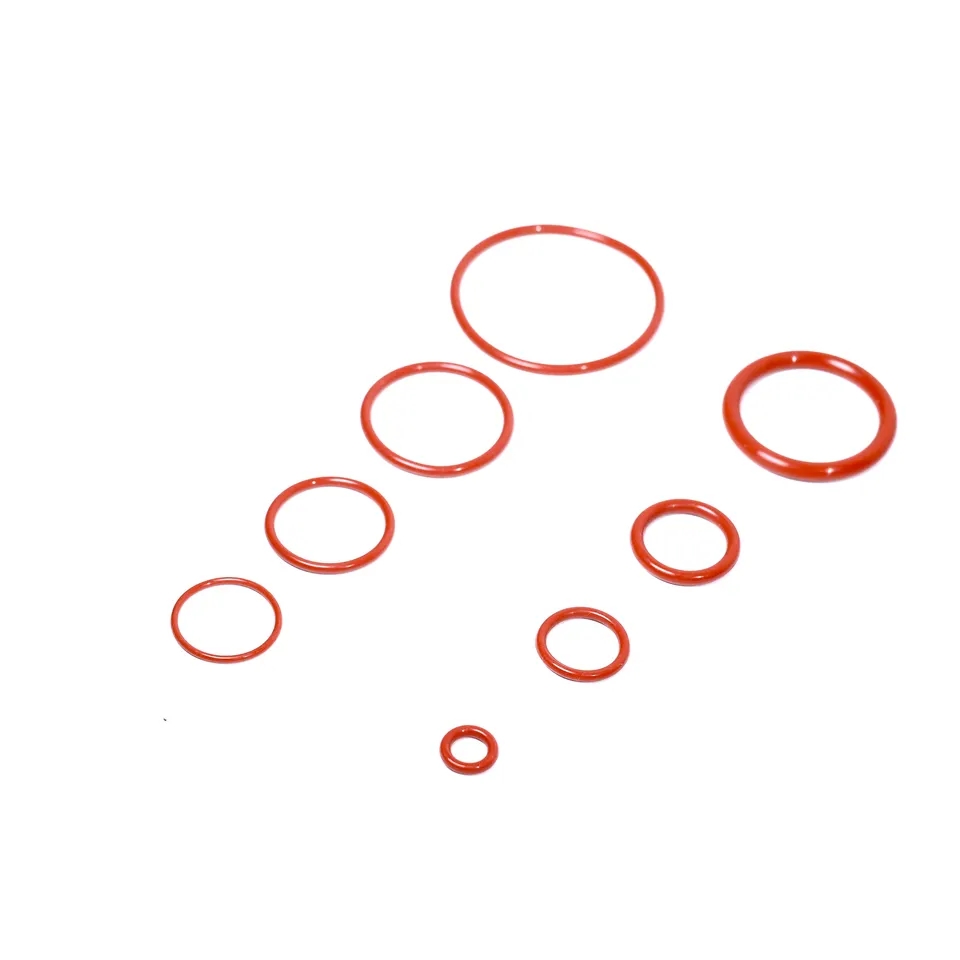

Rubber O-Rings are circular elastomeric seals, typically crafted from high-quality rubber compounds, designed to fit precisely within the grooves of mating parts, forming a seal that guards against leaks and maintains system integrity.

Advantages of Rubber O-Rings:

Versatility: Rubber O-Rings come in various sizes, materials, and configurations, making them suitable for an extensive spectrum of applications, from hydraulic systems to household appliances.

Sealing Excellence: Their precision in creating airtight and watertight seals is unparalleled, ensuring leak prevention and the smooth operation of systems even under the most demanding conditions.

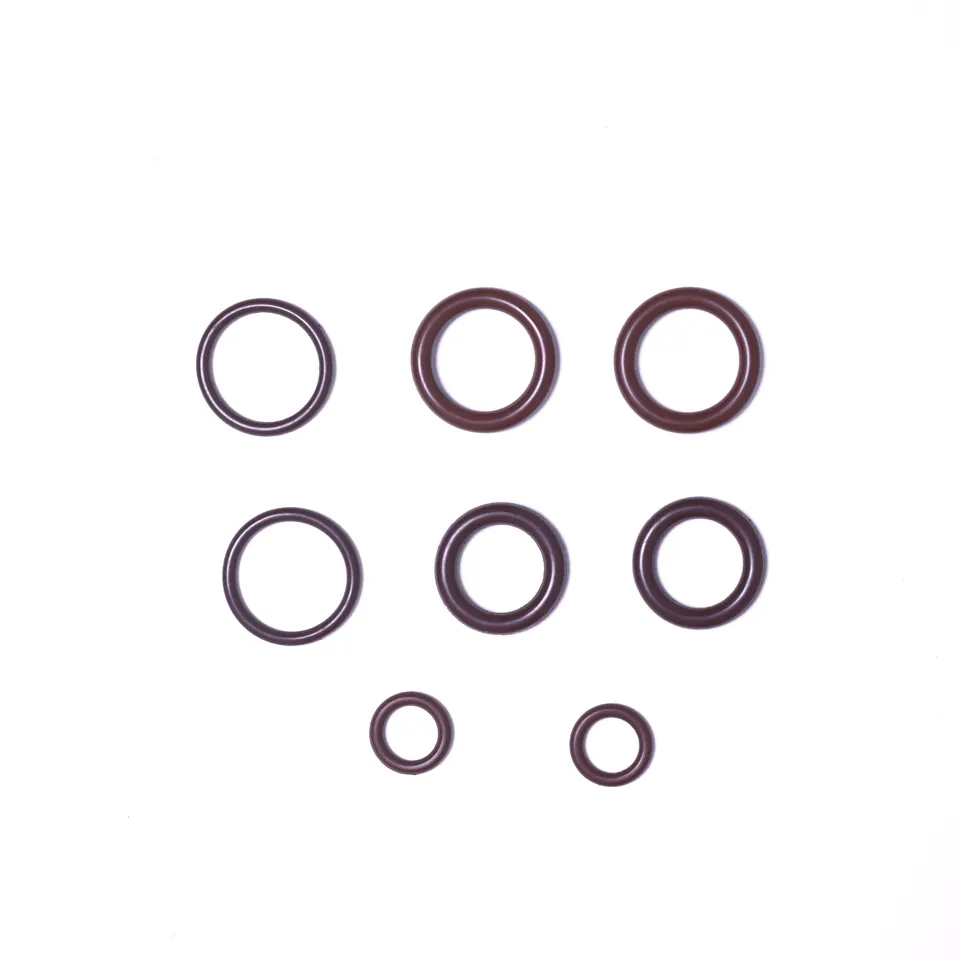

Chemical Resistance: Rubber O-Rings can be engineered from diverse rubber compounds, each offering resistance to specific chemicals, making them invaluable in environments where exposure to corrosive substances is a constant concern.

Temperature Tolerance: These O-Rings exhibit remarkable tolerance to a wide range of temperatures, ensuring they remain reliable in both extreme heat and cold.

Cost-Effective: Rubber O-Rings provide a cost-effective sealing solution, requiring minimal maintenance and replacement, ultimately reducing operational costs.

Customization: They can be tailored to fit unique profiles and dimensions, ensuring a precise sealing solution for specialized applications.

Shock Absorption: In addition to their sealing capabilities, Rubber O-Rings possess shock-absorbing properties, safeguarding delicate components from damage due to vibrations and impacts.

Applications of Rubber O-Rings:

Automotive Industry: Rubber O-Rings are the unsung heroes of automotive engines, transmissions, and hydraulic systems, averting fluid leaks and upholding optimal performance.

Hydraulic Systems: O-Rings play a pivotal role in hydraulic equipment, guaranteeing the integrity of fluid transfer in construction machinery and industrial applications.

Plumbing: These rings provide steadfast seals in plumbing systems, thwarting water leaks and ensuring a secure water supply in both residential and commercial buildings.

Medical Devices: Rubber O-Rings are the backbone of medical equipment, where precision and biocompatibility are paramount, ensuring the safe and sterile operation of devices.

Aerospace: In the aerospace sector, they are indispensable in applications such as fuel systems and engines, where precision and reliability are non-negotiable.

In Conclusion:

Rubber O-Rings, often unnoticed, stand as the epitome of precision sealing, guaranteeing the integrity and dependability of diverse systems and applications. Their distinctive attributes, encompassing versatility, impeccable sealing, and resistance to chemicals, have established them as the preferred choice for professionals and industries worldwide. Whether your endeavors involve the complexities of automotive engineering, hydraulic systems, or plumbing solutions, Rubber O-Rings offer the precision and reliability required to seal with confidence. Explore the realm of Rubber O-Rings and encounter their enduring performance, ensuring the success of your projects, regardless of their intricacy or magnitude.