Sealing Solutions: The Role of Rubber Gasket Sheets in Industry

Introduction: In the intricate world of industrial processes, where precision, safety, and reliability are non-negotiable, rubber gasket sheets quietly but effectively play a crucial role. These unassuming flat materials serve as the unsung heroes of leak prevention in a wide array of industrial applications. In this article, we delve into the world of rubber gasket sheets, exploring their importance, diverse applications, material variations, and the way they underpin efficient, cost-effective, and dependable operations in various industries.

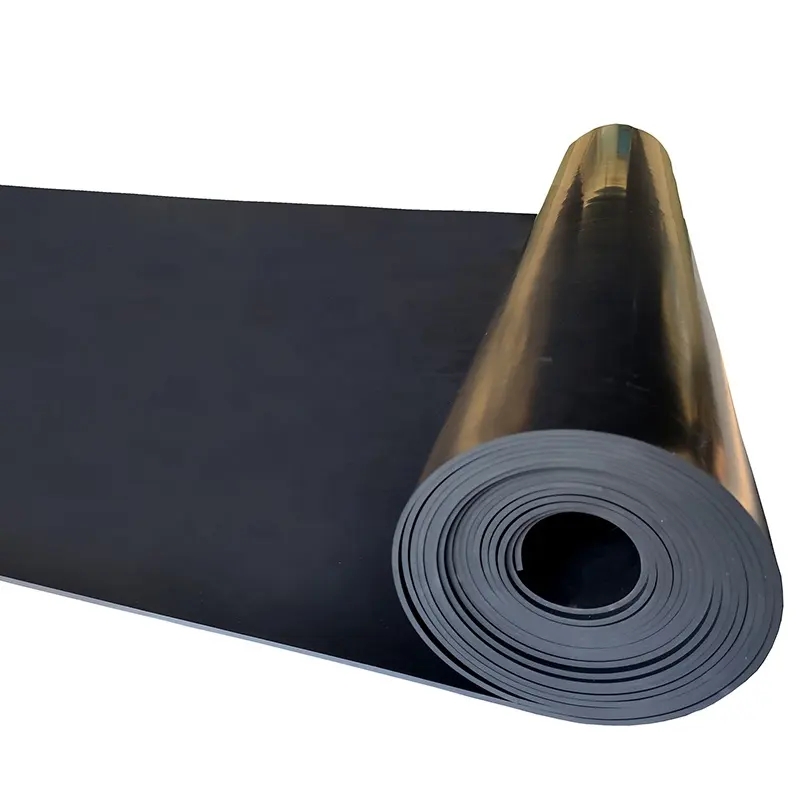

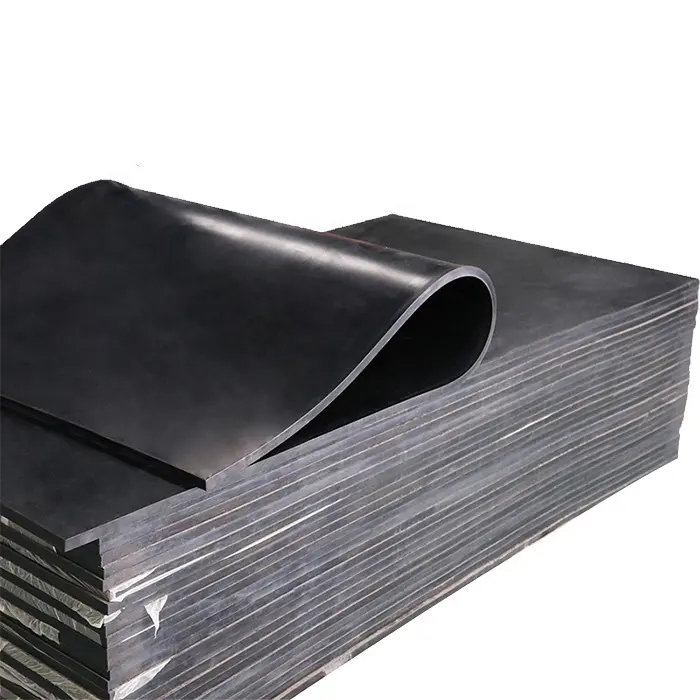

Versatile Applications: Rubber gasket sheets are the backbone of leak prevention across numerous industries. Their versatility makes them invaluable in sectors such as manufacturing, automotive, aerospace, and chemical processing. These sheets are meticulously designed to establish secure, watertight seals, eliminating the risk of costly leaks and ensuring the uninterrupted flow of operations. Common applications include sealing pipe flanges, pumps, heat exchangers, and components within machinery and equipment.

Material Variations: Rubber gasket sheets come in various materials, each tailored to specific needs:

Nitrile Rubber (NBR): Known for its resistance to oils, fuels, and chemicals, NBR gasket sheets are essential in automotive and hydraulic systems.

Silicone Rubber: With outstanding high-temperature resistance, silicone gasket sheets are vital in industries like food processing, pharmaceuticals, and the manufacturing of medical equipment.

Neoprene Rubber (CR): Celebrated for its exceptional weather resistance, neoprene gasket sheets find their home in outdoor environments, including the construction and marine sectors.

EPDM Rubber: EPDM gasket sheets excel in sealing against water and steam, making them indispensable in plumbing and HVAC systems.

The Significance of Rubber Gasket Sheets: The primary function of rubber gasket sheets is to provide dependable, enduring seals, ensuring efficient and leak-free operations. Their advantages include:

Leak Prevention: Rubber gasket sheets establish a reliable barrier, preventing the escape of fluids and gases, and thus averting costly leaks.

Chemical Resistance: Depending on the material, rubber gasket sheets can withstand a wide range of chemicals, making them suitable for demanding industrial settings.

Temperature Resilience: These gasket sheets maintain their structural integrity in extreme temperature conditions, from freezing cold to scorching heat.

Vibration Dampening: Rubber gasket sheets efficiently absorb shocks and vibrations, enhancing the lifespan of machinery and equipment.

Economic and Environmental Benefits: The significance of rubber gasket sheets transcends mere operational efficiency. By preventing leaks and reducing maintenance demands, they lead to cost savings and contribute to a cleaner, more sustainable working environment. Reduced maintenance means fewer disruptions, lower repair costs, and minimized downtime.

Conclusion: Rubber gasket sheets, while often working behind the scenes, are the unsung heroes of industrial processes. They are the invisible shield that guarantees efficiency, cost-effectiveness, and reliability across various industries. As industries evolve and technology advances, rubber gasket sheets will continue to play a pivotal role in maintaining operational excellence, reducing costs, and ensuring the success of diverse industrial applications. They are, without a doubt, the silent champions of leak-free operations.