Silicone Seal Strips: The Ultimate Sealing and Insulation Solution

Introduction: Silicone seal strips have emerged as the unsung heroes of the sealing and insulation world, celebrated for their remarkable properties and diverse applications. In this comprehensive guide, we embark on a journey into the world of silicone seal strips, revealing their unique characteristics, benefits, and the wide range of applications that depend on their exceptional capabilities. Whether you are a professional seeking advanced solutions or a DIY enthusiast aiming to enhance your projects, this article offers a thorough exploration of silicone seal strips and their outstanding features.

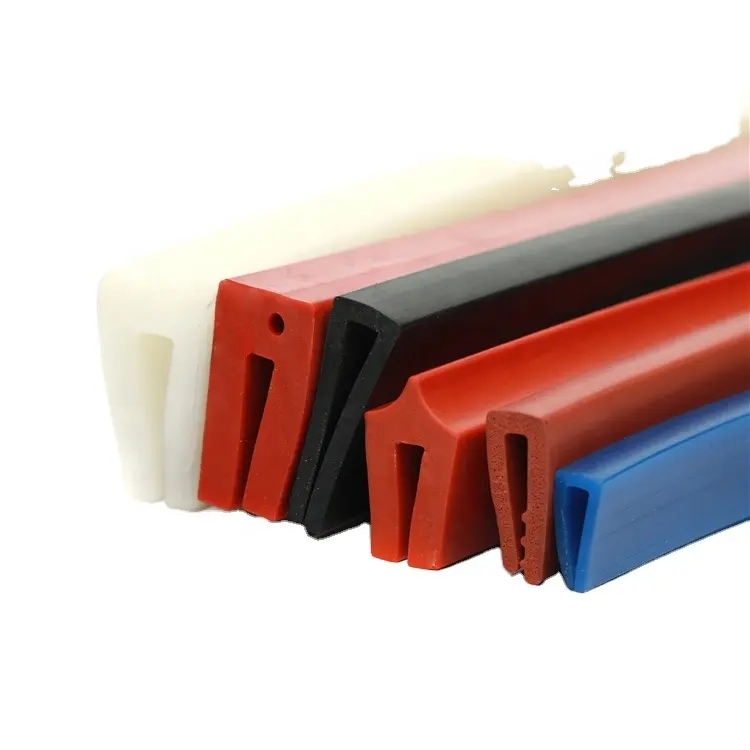

Exploring the Versatility of Silicone Seal Strips:

Silicone seal strips, primarily composed of silicone rubber, have been meticulously engineered to provide top-tier sealing, insulation, and protection. These strips come equipped with a diverse range of properties that distinguish them as exceptional solutions.

Revealing the Benefits of Silicone Seal Strips:

Temperature Tolerance: Silicone seal strips excel in their ability to endure extreme temperatures, operating seamlessly within a wide temperature range, spanning from -40°C to 200°C. This adaptability makes them ideal for applications exposed to dramatic temperature fluctuations.

Weather Resistance: Silicone’s natural resistance to UV radiation and ozone equips silicone seal strips to endure even the most challenging weather conditions, including relentless sunlight and heavy rainfall.

Chemical Resilience: Silicone seal strips are renowned for their exceptional resistance to a wide spectrum of chemicals, acids, and solvents. This unique attribute makes them the preferred choice for safeguarding against corrosive substances, particularly in industries such as chemical manufacturing and transportation.

Flexibility and Adaptability: Silicone seal strips shine in their remarkable flexibility and elasticity, allowing them to provide a secure, conforming seal on irregular shapes and surfaces. This feature is highly valued in industries such as automotive, construction, and manufacturing.

Electrical Insulation: Silicone seal strips boast superior electrical insulation properties, positioning them as the top choice for electronic and electrical applications. They play a pivotal role in sealing electrical enclosures and protecting sensitive components from environmental elements.

Non-Toxic and Food-Grade Varieties: Silicone seal strips come in non-toxic and FDA-compliant versions, ensuring safety and compliance in applications within the food and pharmaceutical sectors.

Diverse Applications of Silicone Seal Strips:

Construction and Architecture: The construction industry relies on silicone seal strips to seal gaps around doors and windows, effectively preventing air and water infiltration. These strips also contribute significantly to enhancing the energy efficiency and weather resistance of curtain wall systems.

Automotive Industry: In the automotive sector, silicone seal strips silently play a crucial role, sealing doors, windows, and engine compartments, making substantial contributions to sound insulation and weather protection.

Electronics: The electronics industry depends on silicone seal strips to protect electronic components, ensuring uninterrupted functionality, even in challenging environments.

Aerospace and Aviation: Silicone seal strips are vital in aircraft, sealing critical components and maintaining the cabin’s integrity, ensuring passenger safety.

Industrial Equipment: Manufacturing settings benefit from silicone seal strips, effectively shielding sensitive machinery and equipment from dust, moisture, and contaminants.

Medical Devices: Silicone seal strips meet rigorous quality and safety standards in the medical equipment sector, where they are instrumental in ensuring patient safety and device functionality.

In conclusion, silicone seal strips offer versatile solutions for sealing and insulating across a multitude of applications and industries. Their exceptional properties, encompassing temperature resistance, weather endurance, flexibility, and chemical resilience, position them as the ultimate choice for professionals seeking efficiency and durability in their projects. Whether your focus is on construction, automotive, electronics, or any other industry, silicone seal strips stand as the ultimate sealing and insulation solution, delivering unmatched performance and protection.