Rubber Seal Strips: The Versatile Guardians of Sealing

Introduction:

Invisible yet indispensable, rubber seal strips are the unsung heroes in the world of sealing solutions. They play a crucial role in various applications, silently ensuring protection, insulation, and weatherproofing. This article delves into the versatile world of rubber seal strips and their significance in different industries.

A World of Material Choices:

EPDM, Neoprene, Silicone: Rubber seal strips are available in a variety of materials. EPDM offers excellent weather resistance, neoprene excels in chemical resistance, and silicone provides flexibility and high-temperature tolerance.

Customization for Precision:

Rubber seal strips can be customized to fit specific dimensions and shapes, ensuring a perfect seal for windows, doors, machinery, and more.

Simplified Installation with Adhesive Backing:

Many rubber seal strips come with adhesive backing, simplifying the installation process and saving both time and effort.

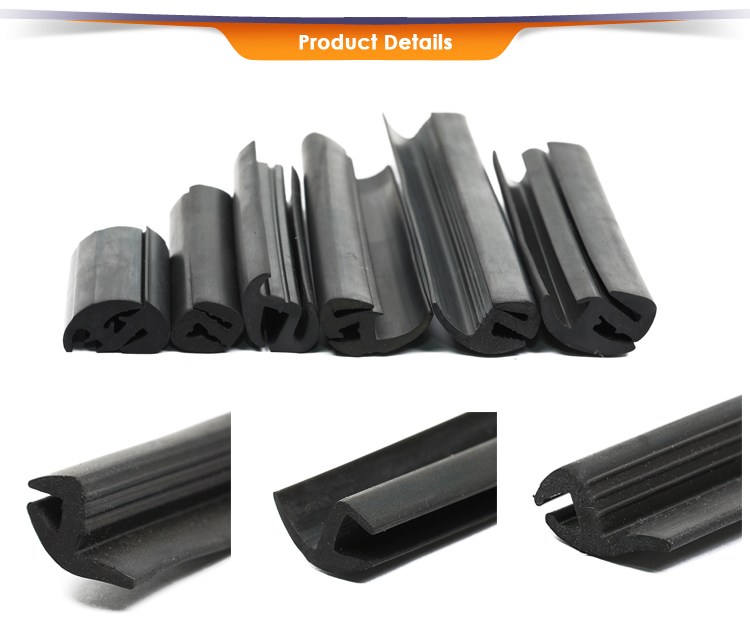

Shapes and Profiles for Every Need:

Available in a multitude of shapes, including D-shaped, P-shaped, and more, rubber seal strips cater to various sealing requirements across different industries.

Versatile Applications:

Automotive: Rubber seal strips are essential for sealing doors, windows, and hoods, reducing noise and ensuring effective weatherproofing in vehicles.

Construction: They create watertight and airtight seals in windows and doors, enhancing energy efficiency in buildings.

Manufacturing: In the manufacturing sector, rubber seal strips reduce vibration and noise in machinery while acting as a barrier against dust and contaminants.

Home Improvement: Homeowners benefit from these strips by sealing gaps around windows and doors, leading to better insulation and reduced energy costs.

Key Advantages:

Weather Resistance: Rubber seal strips effectively seal out rain, wind, and other harsh elements, ensuring that interiors remain protected in all weather conditions.

Noise Reduction: They provide acoustic insulation, creating quieter and more comfortable indoor environments, improving quality of life in both residential and industrial settings.

Energy Efficiency: By sealing gaps and preventing air leakage, rubber seal strips contribute to energy efficiency by reducing heating and cooling costs, ultimately saving money and reducing environmental impact.

Dust and Insect Barrier: These strips create a protective barrier against dust, pollutants, and insects, maintaining a clean and hygienic environment.

Vibration Dampening: Rubber seals absorb and dampen vibrations, enhancing the lifespan of machinery and improving their overall performance.

Conclusion:

In conclusion, rubber seal strips serve as the guardians of sealing, protecting and insulating in various applications. Their versatility, ease of installation, and durability make them a popular choice in industries ranging from automotive to construction. Whether you’re a professional or a DIY enthusiast, investing in high-quality rubber seal strips ensures effective sealing and protection for your projects, making them the unsung heroes you can rely on.