Rubber O-Rings: The Guardians of Industrial Sealing Solutions

Introduction: In the world of industrial machinery and engineering, there exists an unassuming yet highly critical component – the Rubber O-Ring. These circular sealing wonders silently serve as the guardians of leak-proof seals, preserving the integrity of machinery and equipment across various industries. In this article, we will embark on a journey through the realm of Rubber O-Rings, uncovering their composition, versatile applications, and their irreplaceable role in the modern industrial landscape.

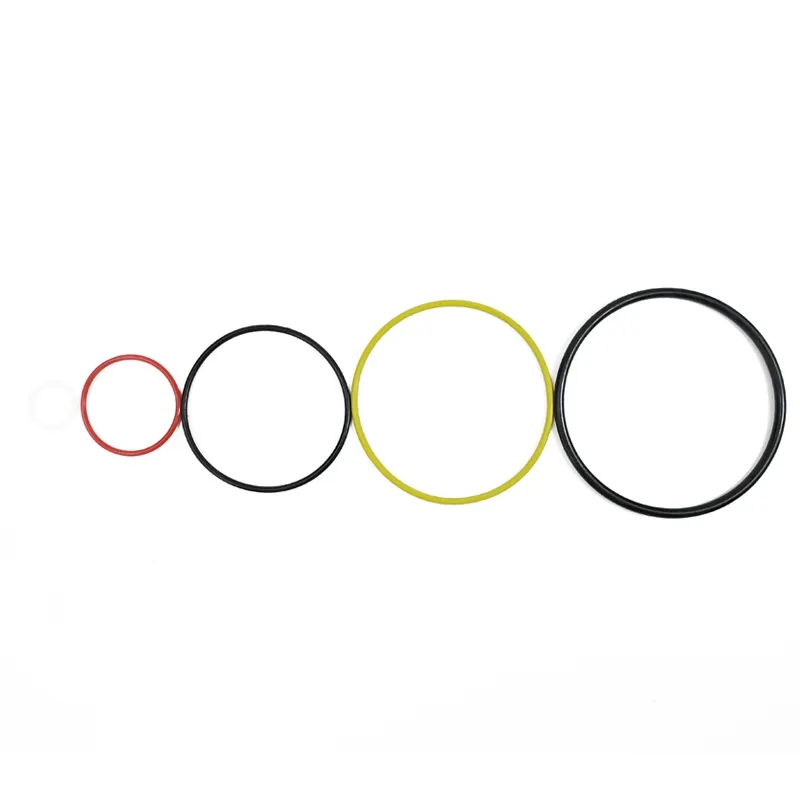

Composition and Structure: Rubber O-Rings are primarily molded from elastomeric materials, including nitrile, silicone, EPDM, and Viton. These materials are carefully selected for their ability to endure extreme temperatures, resist a multitude of chemicals, and stand strong against harsh environmental conditions. The O-Ring’s simple yet effective circular cross-section design allows it to excel in sealing applications. Moreover, the versatility of Rubber O-Rings is highlighted by their ability to be customized into various sizes and shapes to cater to specific sealing requirements.

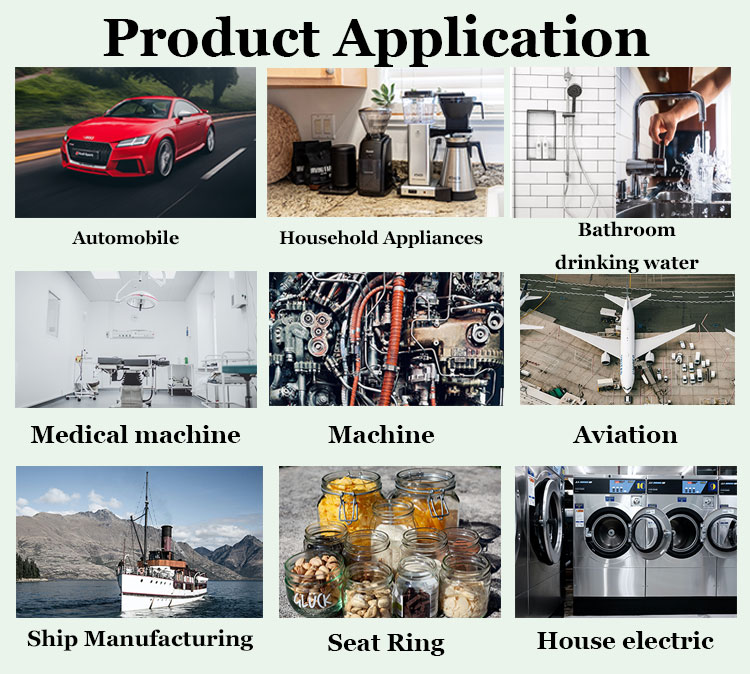

Versatile Applications:

Automotive Industry: Rubber O-Rings are a linchpin in the automotive sector, sealing fluids and gases in engines, transmissions, and braking systems. Their steadfast performance under fluctuating temperatures and exposure to chemicals ensures the safety and efficiency of vehicles.

Aerospace Industry: In the aerospace sector, Rubber O-Rings play a critical role in hydraulic systems, engines, and fuel lines. Their ability to endure the most extreme conditions is vital for ensuring the safety and reliability of air travel.

Industrial Machinery: O-Rings serve as the backbone of industrial machinery, sealing hydraulic and pneumatic systems. This guarantees the smooth and efficient operation of manufacturing plants and factories.

Medical and Pharmaceutical Devices: The medical and pharmaceutical industries rely on Rubber O-Rings for sealing applications in equipment and devices. O-Rings’ biocompatibility and resistance to sterilization make them an undisputed choice for ensuring patient safety and process integrity.

Oil and Gas Exploration: In the oil and gas industry, O-Rings are instrumental in sealing valves, pumps, and drilling equipment, preventing leaks and safeguarding operations and the environment.

Key Benefits:

Effective Sealing: Rubber O-Rings are unsurpassed in their sealing efficiency, adept at preventing leaks and contamination.

Resistance to Environmental Factors: They are capable of withstanding extreme temperatures, resisting harsh chemicals, and enduring challenging environmental conditions.

Durability: O-Rings exhibit an impressive service life, which ultimately reduces maintenance and replacement costs.

Cost-Efficiency: They offer a cost-effective sealing solution, adaptable to a wide array of industries.

Versatility: O-Rings are available in various materials and sizes, making them suitable for a diverse range of applications.

Conclusion: While often overlooked, Rubber O-Rings are undeniably indispensable in modern engineering and manufacturing. They are the silent protectors ensuring the reliability and safety of equipment and systems across an array of industries. Incorporating Rubber O-Rings into your projects can substantially enhance equipment performance and durability while safeguarding against leaks and contamination.