Silicone Seal Rings: The Sealing Champions of Industry

Introduction:

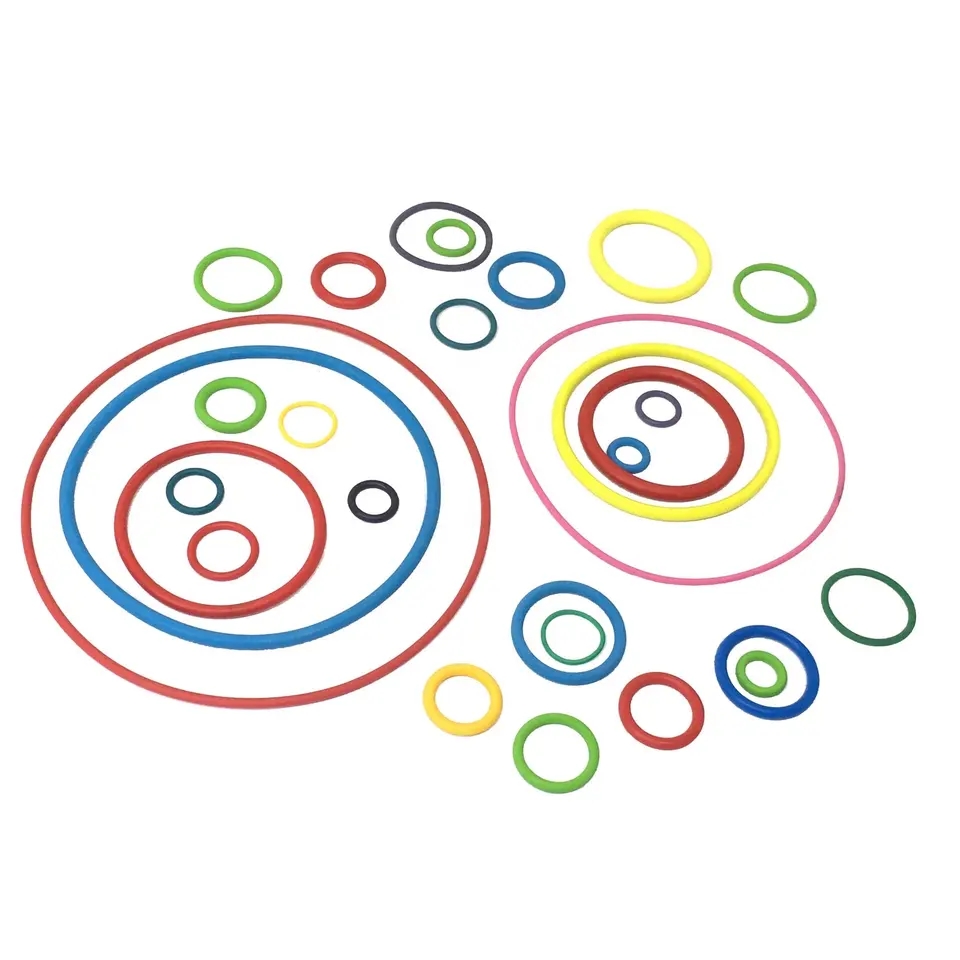

In the world of sealing solutions, silicone seal rings have risen to the top as the champions of industry, celebrated for their versatility and unparalleled performance across a multitude of applications. In this article, we explore the realm of silicone seal rings, uncovering their unique attributes, practical advantages, and the wide-ranging applications that make them a first-choice solution for professionals and DIY enthusiasts alike.

The Versatility of Silicone Seal Rings: Sealing Excellence

Silicone seal rings are meticulously engineered from silicone rubber, a material known for its exceptional properties that distinguish it in the field of sealing technology.

Advantages of Silicone Seal Rings:

Temperature Tolerance: Silicone seal rings excel in extreme temperature conditions, ensuring a dependable seal in both high-temperature and cryogenic environments, a critical feature in applications ranging from automotive engines to refrigeration systems.

Chemical Resistance: These rings exhibit remarkable resistance to a wide spectrum of chemicals, acids, and solvents, making them indispensable in industries where corrosive substances are present, such as chemical processing and laboratories.

Weather Endurance: Silicone seal rings are UV and weather-resistant, making them ideal for outdoor applications, including architectural construction and marine equipment.

Flexibility: Their impressive flexibility allows silicone seal rings to conform to various shapes and surfaces, ensuring a secure, custom-tailored seal in plumbing, hydraulic systems, and beyond.

Low Compression Set: Silicone seal rings maintain their original shape even after prolonged compression, reducing the risk of leaks and ensuring long-lasting performance in high-pressure systems.

Biocompatibility: Silicone’s biocompatible and non-reactive nature makes these rings suitable for medical and pharmaceutical applications, including implantable devices and drug delivery systems.

Electrical Insulation: Silicone seal rings offer excellent electrical insulation properties, ensuring safety in electrical connections and components in both industrial and household settings.

Longevity: Silicone seal rings are known for their durability, reducing maintenance costs and contributing to sustainable operations in industries such as water treatment and oil and gas.

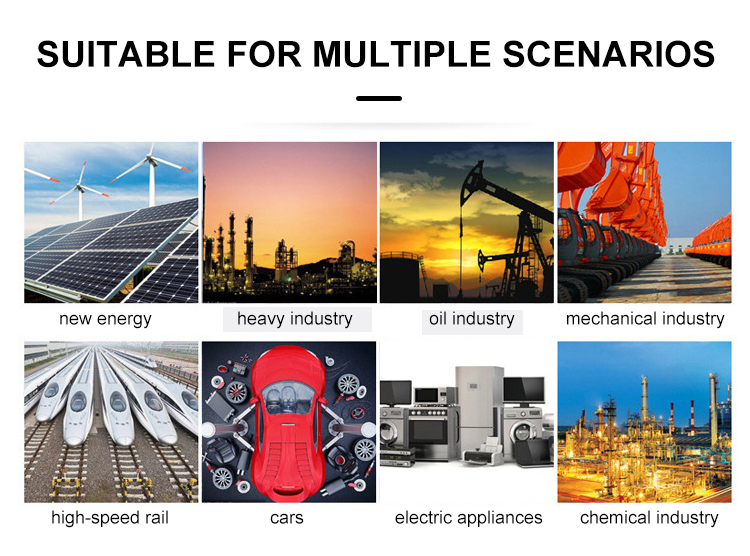

Applications of Silicone Seal Rings:

Automotive Industry: Silicone seal rings are integral to engines, transmissions, and exhaust systems, providing reliable seals in demanding conditions.

Medical Devices: In medical applications, these rings offer sterile and biocompatible sealing solutions in devices such as syringes, IV systems, and surgical instruments, ensuring patient safety and precision.

Aerospace: The aerospace sector relies on silicone seal rings for reliable seals in aircraft systems, from fuel lines and hydraulic systems to avionics.

Industrial Machinery: Silicone seal rings play a pivotal role in maintaining efficiency and reliability in various industrial processes, from heavy manufacturing equipment to precision instruments.

Food and Beverage: These rings are essential in sealing food processing equipment, ensuring hygienic and contamination-free production in the food and beverage industry.

In Conclusion:

Silicone seal rings are the undisputed champions of sealing solutions, known for their adaptability and resilience across numerous industries. Their unique attributes, including temperature tolerance, chemical resistance, and longevity, make them the preferred choice for sealing and insulating applications. Whether you’re tackling industrial challenges, healthcare requirements, or home improvement projects, silicone seal rings offer a reliable, versatile, and durable sealing solution. Embrace the adaptability and long-lasting performance of silicone seal rings for a seamless sealing experience, ensuring the success of your projects, regardless of their complexity or scale.