Rubber Gaskets: Sealing Solutions for Every Industry

Introduction: In the world of industrial engineering and manufacturing, the need for reliable and efficient sealing solutions is ever-present. Rubber gaskets, often unsung heroes, play a pivotal role in ensuring airtight and leak-free connections in a wide range of applications. This article delves into the world of rubber gaskets, exploring their composition, diverse applications, and the crucial role they play in various industries.

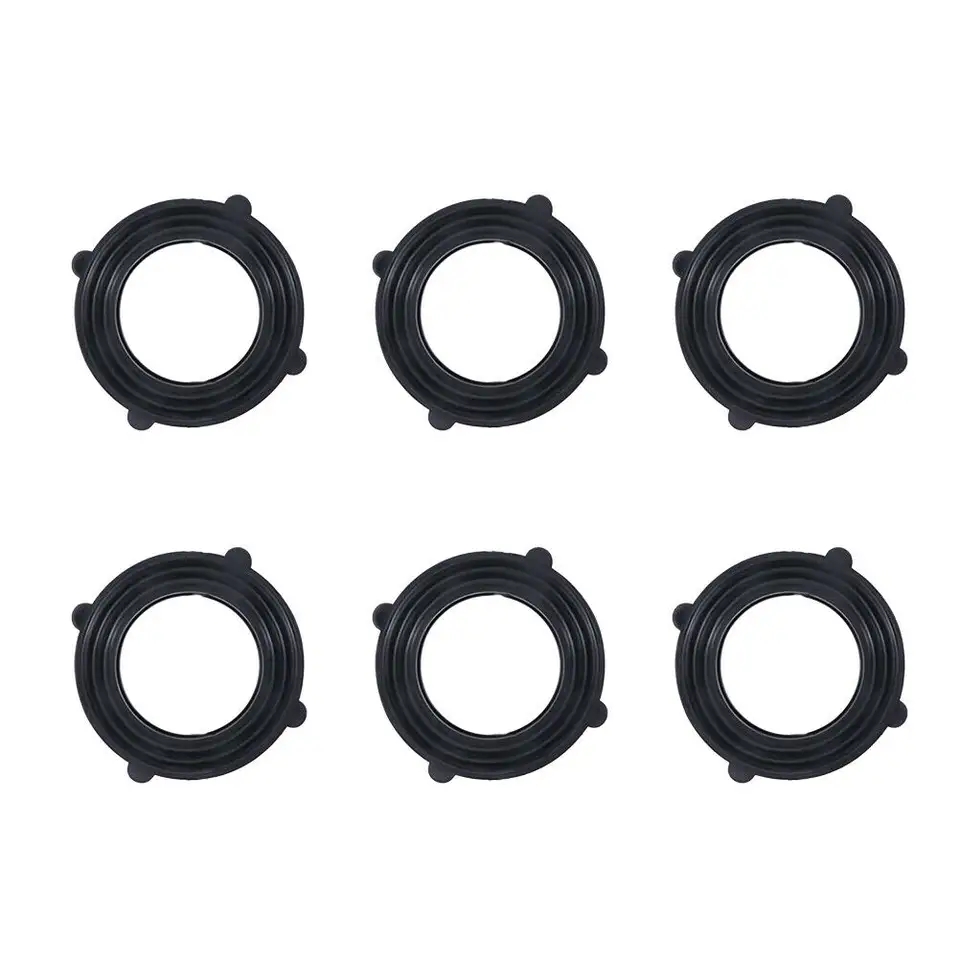

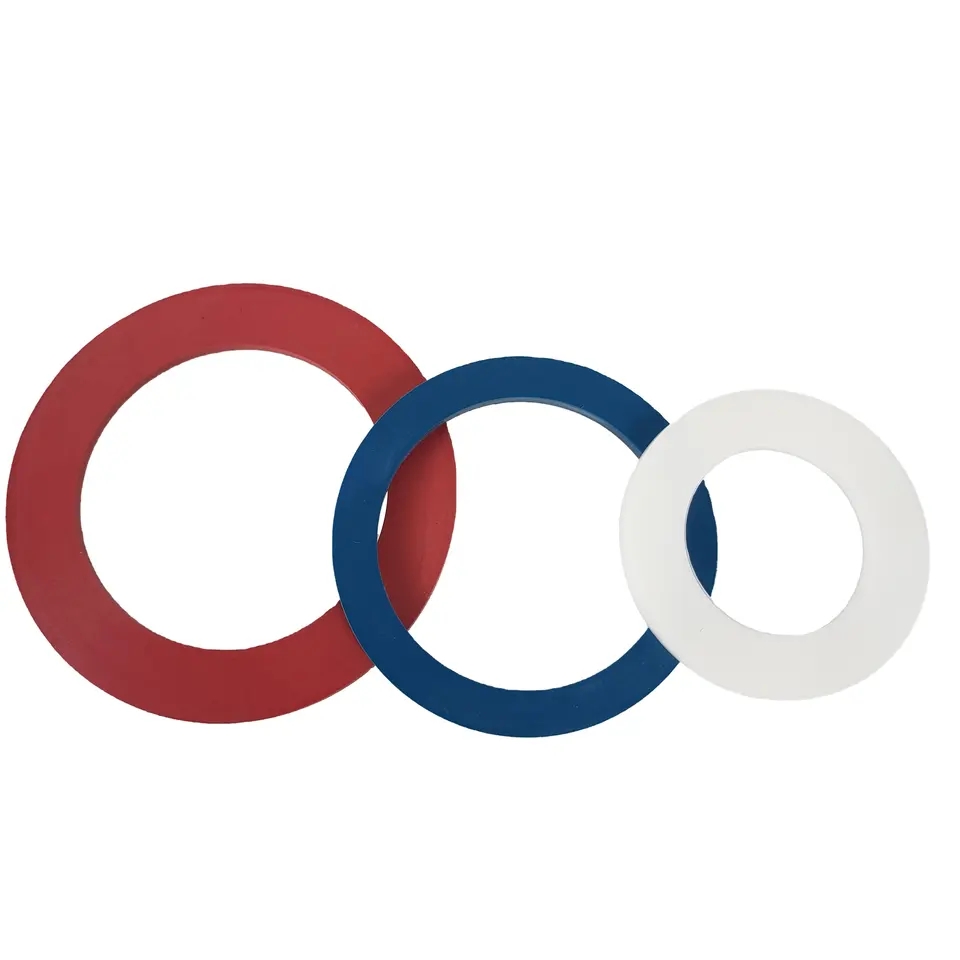

The Anatomy of Rubber Gaskets: Rubber gaskets are precision-engineered components, typically made from elastomeric materials like neoprene, EPDM, silicone, or nitrile rubber. Their unique composition provides them with the properties that make them indispensable for sealing purposes. The flexibility and resilience of rubber gaskets, combined with their ability to withstand temperature extremes, chemicals, and pressure, make them suitable for diverse applications.

The Versatility of Rubber Gaskets:

Automotive Sector: Rubber gaskets find extensive use in the automotive industry, sealing engine components, transmissions, and even vehicle doors. Their ability to withstand the demands of fluctuating temperatures and exposure to engine fluids is crucial for automotive reliability.

Industrial Machinery: In the world of manufacturing, rubber gaskets are essential for sealing machinery components. They prevent leaks of oil, coolant, and hydraulic fluids, contributing to the efficiency and longevity of industrial equipment.

Plumbing and HVAC: Rubber gaskets are commonly used in plumbing and HVAC systems to create watertight seals. Their flexibility and resistance to temperature variations are ideal for withstanding the demands of these applications.

Aerospace Engineering: The aerospace industry relies on rubber gaskets for their ability to maintain airtight seals in critical systems. The precise sealing capabilities of rubber gaskets are essential in the rigorous and demanding conditions of aviation.

Conclusion: Rubber gaskets may be inconspicuous components, but their contribution to sealing reliability and efficiency in various industries is significant. From the automotive sector to aerospace engineering, they continue to be the trusted choice for creating airtight and leak-free connections, ensuring the smooth operation of machinery and systems. Whether you’re driving a car, operating industrial equipment, or flying in an aircraft, rubber gaskets are working silently behind the scenes to keep everything securely sealed and functioning efficiently.