The Advantages of Rubber Seal Strips in Various Applications

Introduction:

Rubber seal strips are a versatile and indispensable component used across numerous industries for sealing, insulating, and protecting against the elements. This article will explore the numerous advantages that rubber seal strips offer in different applications, shedding light on the versatility and effectiveness of these sealing solutions.

A Multitude of Materials:

EPDM, Neoprene, Silicone: Rubber seal strips are available in various materials, each with unique properties. EPDM offers excellent weather resistance, neoprene excels in chemical resistance, and silicone provides flexibility and high-temperature tolerance.

Customization for Precision:

Rubber seal strips can be customized to fit specific dimensions and shapes, ensuring a perfect seal in any application, from windows and doors to machinery and vehicles.

Easy Installation with Adhesive Backing:

Many rubber seal strips come with adhesive backing, simplifying installation and saving time, making them user-friendly for professionals and DIY enthusiasts.

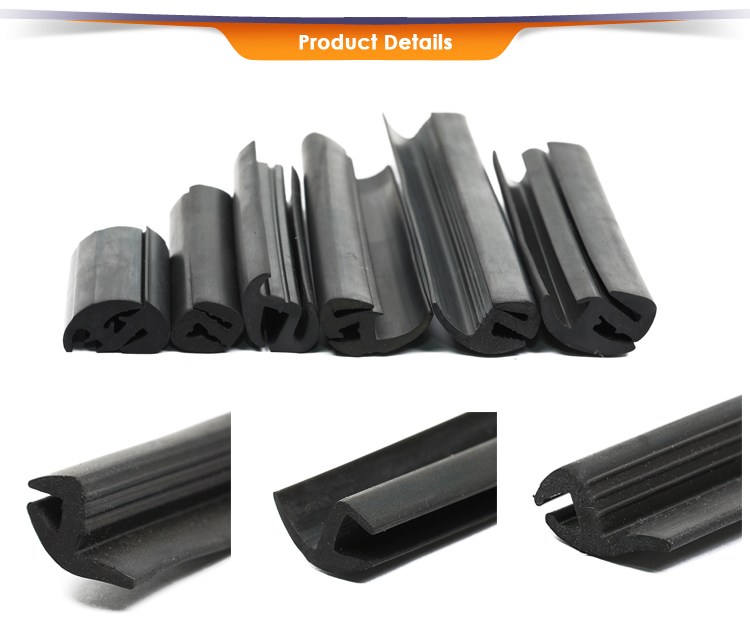

Diverse Shapes and Profiles:

These strips are available in an array of shapes, including D-shaped, P-shaped, and more, making them adaptable to different sealing needs, be it automotive, construction, or manufacturing.

Applications in a Range of Industries:

Automotive: Rubber seal strips are vital for sealing doors, windows, and hoods, reducing noise and ensuring weatherproofing.

Construction: They are used to create water and airtight seals in windows and doors, ultimately improving energy efficiency in buildings.

Manufacturing: In this industry, rubber seal strips reduce vibration and noise in machinery while maintaining a barrier against dust and contaminants.

Home Improvement: Homeowners benefit from these strips by sealing gaps around windows and doors, leading to better insulation and reduced energy costs.

Key Benefits:

Weather Resistance: Rubber seal strips effectively seal out rain, wind, and other elements, safeguarding interiors from harsh weather conditions, making them an ideal choice for outdoor applications.

Noise Reduction: They provide acoustic insulation, ensuring quieter and more comfortable indoor environments, benefiting both residential and industrial spaces.

Energy Efficiency: By sealing gaps and preventing air leakage, rubber seal strips contribute to energy efficiency by reducing heating and cooling costs, ultimately saving money.

Dust and Insect Barrier: These strips act as a barrier against dust, pollutants, and insects, maintaining a clean, hygienic environment in both homes and workplaces.

Vibration Dampening: Rubber seals absorb and dampen vibrations, prolonging the life of equipment and machinery while enhancing their performance.

Conclusion:

In conclusion, rubber seal strips are versatile and essential components in various applications, offering efficient sealing, insulation, and protection against environmental factors. Their adaptability, easy installation, and durability make them a popular choice in multiple industries, including automotive, construction, manufacturing, and home improvement. Choose the right rubber seal strip for your specific needs to enhance your project’s efficiency and longevity.