Rubber Gasket: An Essential Component for Sealing Excellence

Introduction:

Rubber gaskets play a vital role in various industrial applications, ensuring a secure and efficient seal between two surfaces. These versatile sealing components are designed to prevent leaks, protect against contaminants, and maintain the integrity of machinery and equipment. In this article, we will explore the significance of rubber gaskets, their diverse applications, and the key factors to consider when selecting the right gasket for your specific needs.

The Importance of Rubber Gaskets:

Rubber gaskets are made from high-quality elastomeric materials, such as neoprene, silicone, EPDM, and nitrile, known for their excellent resilience and resistance to environmental factors. These gaskets are used in a wide range of industries, including automotive, aerospace, plumbing, and manufacturing, to name just a few. Their primary function is to provide a secure seal, preventing the escape of fluids, gases, or debris, and ensuring the safety and efficiency of various processes.

Applications:

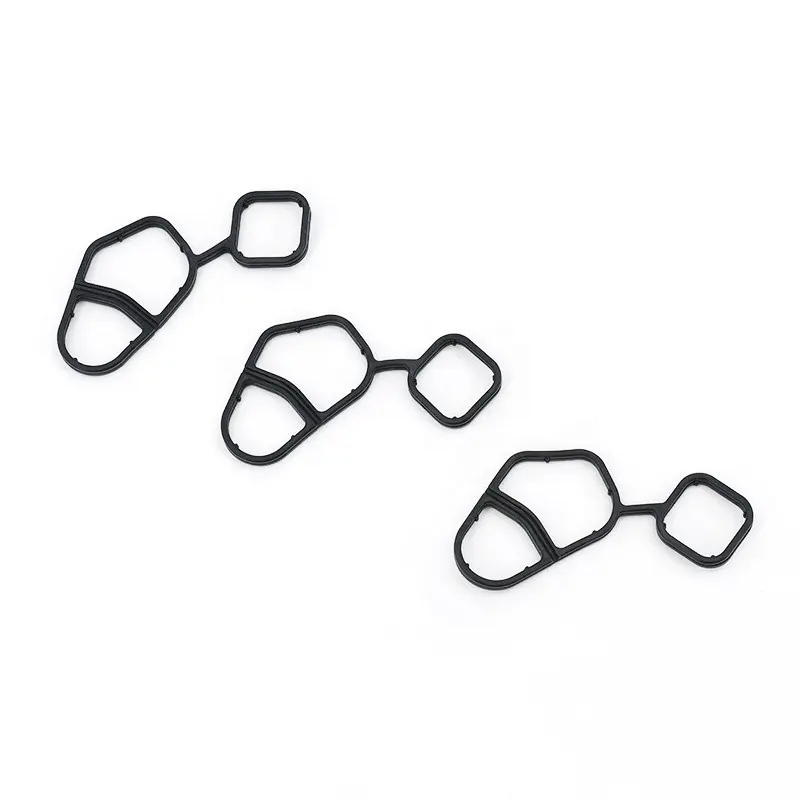

Automotive Industry: Rubber gaskets are essential in vehicles, sealing various components like engine compartments, transmission systems, and exhaust systems. They contribute to fuel efficiency, emission control, and noise reduction.

Plumbing and HVAC: In residential and commercial plumbing systems, rubber gaskets are commonly used in faucets, valves, and pipe connections to prevent water leakage. In HVAC systems, they create a tight seal in ductwork, improving energy efficiency.

Aerospace: The aerospace industry relies on rubber gaskets for critical applications, including engine seals and aircraft windows. These gaskets must meet rigorous performance and safety standards.

Manufacturing: In manufacturing processes, rubber gaskets are used to seal pumps, valves, and tanks, ensuring the integrity of chemical and industrial processes.

Choosing the Right Rubber Gasket:

Selecting the appropriate rubber gasket for your application is crucial to ensure a reliable and long-lasting seal. Here are some factors to consider:

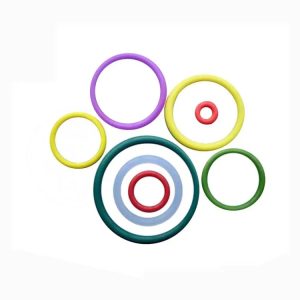

Material: Different elastomers are suitable for various environments. Consider the chemical resistance, temperature tolerance, and durability required for your specific application.

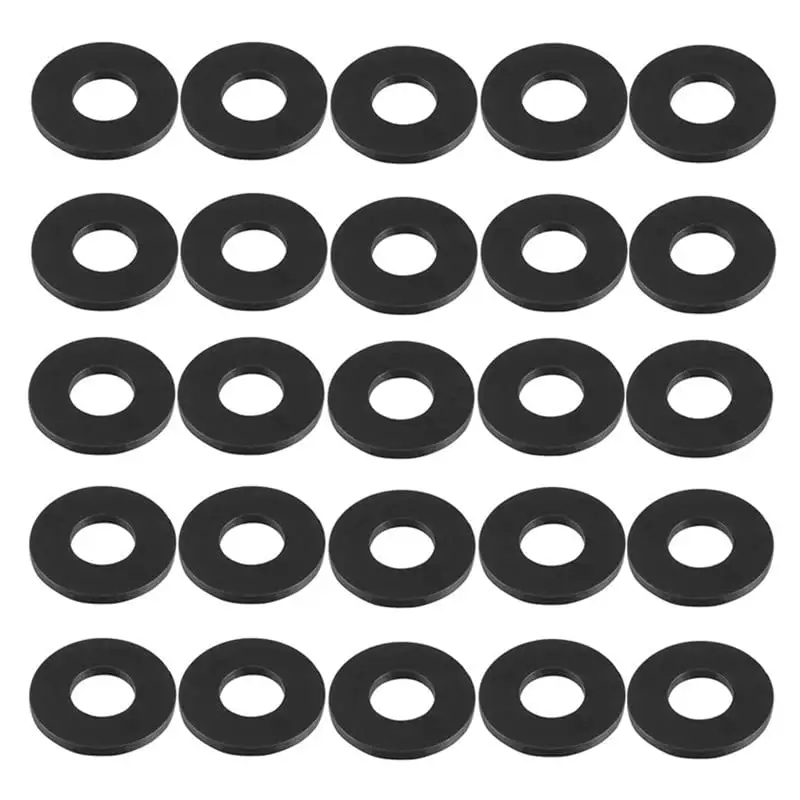

Design: Gaskets come in various shapes and designs, such as O-rings, square-cut gaskets, and flange gaskets. Choose the design that best suits your sealing needs.

Pressure and Temperature: Determine the operating conditions, including pressure and temperature, as these factors affect the gasket’s performance.

Compliance and Certification: Some industries have strict regulations and standards for gasket materials. Ensure your gasket complies with these requirements.

Conclusion:

Rubber gaskets are indispensable components in countless industries, providing reliable sealing solutions for critical applications. Understanding their importance, selecting the right material, and considering the specific requirements of your application are essential steps in ensuring a successful and long-lasting seal. Whether you are in the automotive, aerospace, plumbing, or manufacturing sector, rubber gaskets play a crucial role in maintaining the efficiency and safety of your processes. Choose wisely to ensure sealing excellence with rubber gaskets.