Rubber O-Rings: The Engineered Seal for Industrial Excellence

Introduction: Rubber O-Rings, seemingly inconspicuous yet profoundly essential, serve as the silent guardians of industrial equipment. These circular sealing devices are the unsung heroes that maintain leak-proof seals, ensuring the integrity of machinery and systems across a multitude of industries. In this article, we will explore the world of Rubber O-Rings, delving into their composition, multifaceted applications, and their pivotal role in modern industrial processes.

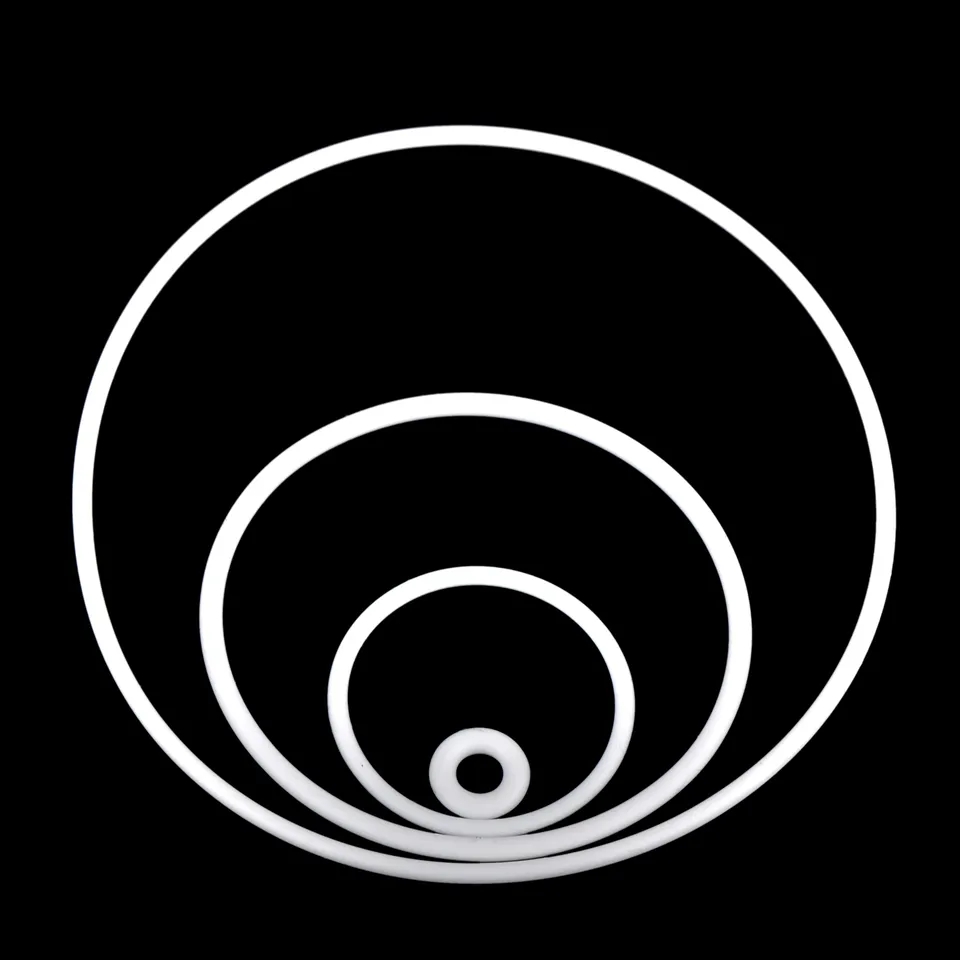

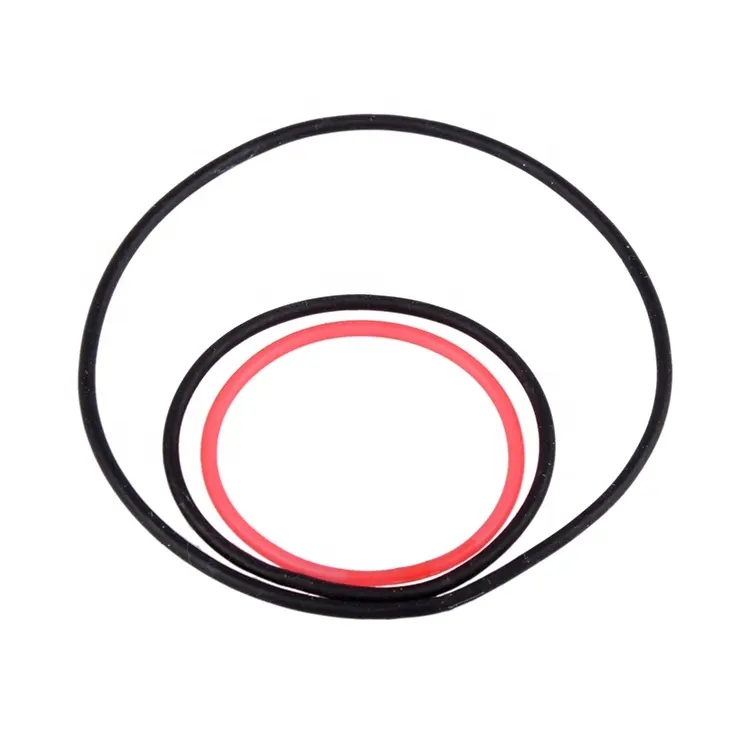

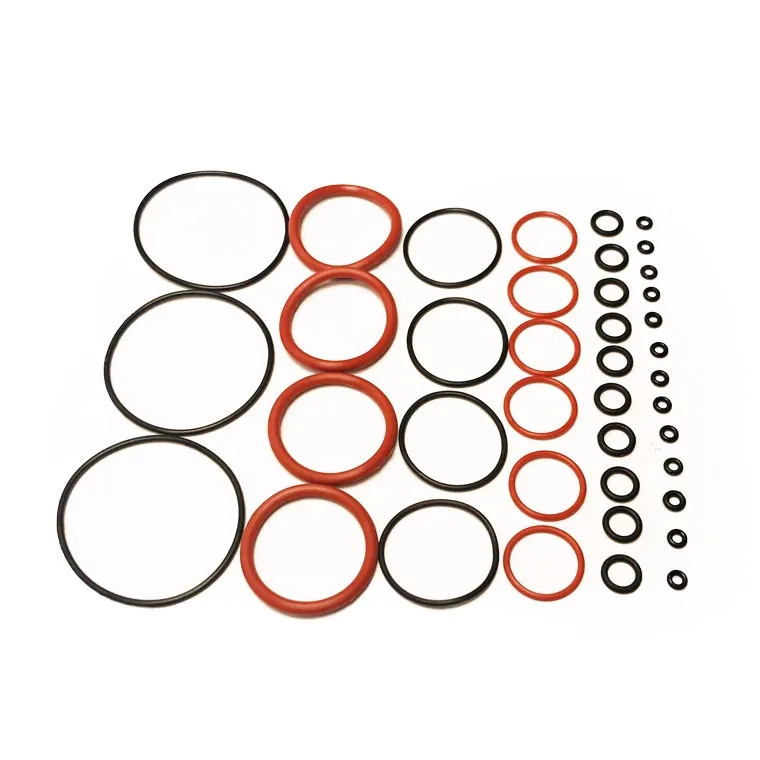

Composition and Structure: Rubber O-Rings are primarily crafted from elastomeric materials, including nitrile, silicone, EPDM, and Viton. These materials are selected for their ability to withstand extreme temperatures, resist a variety of chemicals, and endure the rigors of challenging environmental conditions. The O-Ring’s simple yet effective design, with a circular cross-section, lends itself perfectly to sealing applications. Moreover, these O-Rings can be customized in various sizes and shapes to accommodate specific sealing requirements, providing unmatched versatility and adaptability.

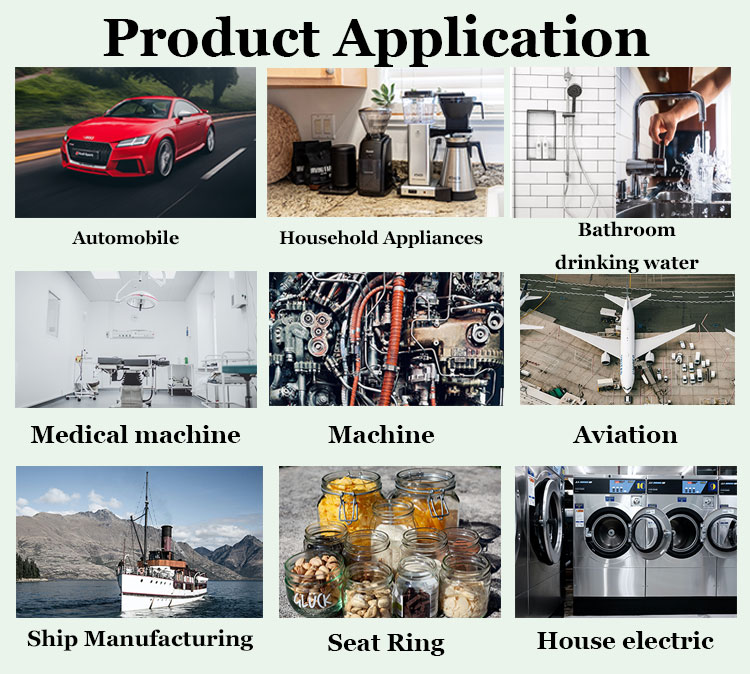

Versatile Applications:

Automotive Industry: Rubber O-Rings are integral to the automotive sector, sealing fluids and gases in engines, transmissions, and braking systems. They excel at maintaining seals under fluctuating temperatures and exposure to chemicals, thereby contributing to vehicle safety and performance.

Aerospace Industry: In the aerospace sector, Rubber O-Rings are essential components in hydraulic systems, engines, and fuel lines. Their ability to endure extreme conditions is critical for ensuring the reliability and safety of air travel.

Industrial Machinery: O-Rings are the cornerstone of industrial machinery, sealing hydraulic and pneumatic systems. This ensures smooth and efficient operations in manufacturing plants and factories.

Medical and Pharmaceutical Devices: The medical and pharmaceutical industries rely on Rubber O-Rings for sealing applications in equipment and devices. O-Rings’ biocompatibility and resistance to sterilization make them a trusted choice for patient safety and process integrity.

Oil and Gas Exploration: In the oil and gas sector, O-Rings play a pivotal role in sealing valves, pumps, and drilling equipment. Their reliability in preventing leaks safeguards operations and the environment.

Key Benefits:

Effective Sealing: Rubber O-Rings excel at preventing leaks and contamination, delivering exceptional sealing performance.

Resistance to Environmental Factors: They can endure extreme temperatures, resist harsh chemicals, and withstand challenging environmental conditions.

Durability: O-Rings boast a long service life, reducing maintenance and replacement costs.

Cost-Efficiency: They offer a cost-effective sealing solution for a wide array of industries.

Versatility: O-Rings are available in various materials and sizes to cater to a diverse range of applications.

Conclusion: Though they may seem unremarkable at first glance, Rubber O-Rings are nothing short of indispensable in modern engineering and manufacturing. They are the dependable safeguards ensuring the reliability and safety of equipment and systems in numerous industries. Incorporating Rubber O-Rings into your projects can substantially enhance equipment performance and longevity while protecting against leaks and contamination.

In the intricate realm of engineering, Rubber O-Rings exemplify the profound impact that simplicity can have, making them an intrinsic element of the modern industrial landscape.