The Unseen Force: Rubber O-Rings in Modern Engineering

Introduction: In the world of modern engineering, there are often unsung heroes quietly working behind the scenes, ensuring the integrity and efficiency of systems. Rubber O-Rings are one such silent force, providing the critical sealing solutions that prevent leaks and contamination across various industries. In this article, we delve into the world of Rubber O-Rings, exploring their composition, versatility, and the indispensable role they play in modern engineering.

Composition and Structure: Rubber O-Rings are typically crafted from elastomeric materials, including nitrile, silicone, EPDM, and Viton. These materials are carefully chosen for their ability to withstand extreme temperatures, resist chemicals, and endure harsh environmental conditions. The O-Ring’s simple circular cross-section design, resembling a toroid or donut, makes it ideal for sealing applications. Furthermore, these O-Rings can be customized in various sizes and shapes to meet specific sealing requirements.

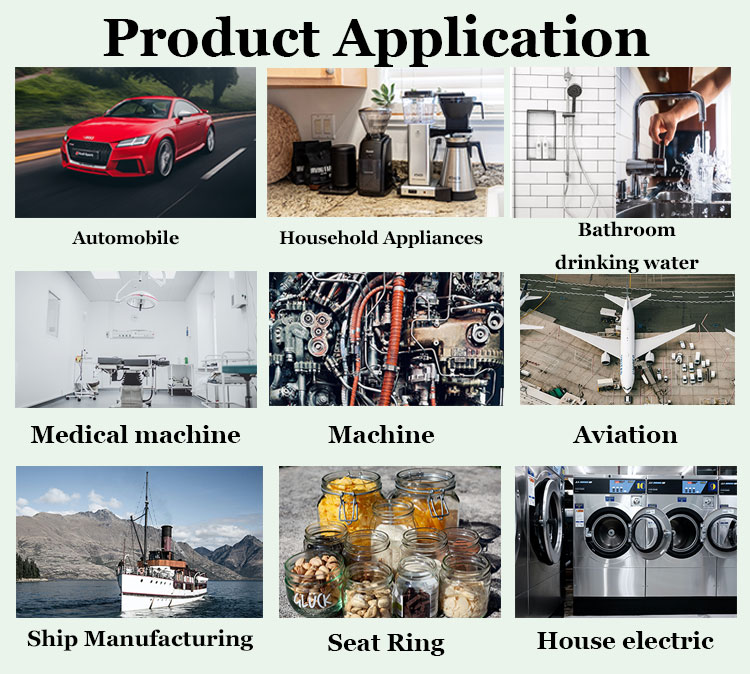

Versatile Applications:

Automotive Industry: Rubber O-Rings are a mainstay in the automotive sector, used to seal fluids and gases in engines, transmissions, and braking systems. They provide reliable sealing even in the face of temperature fluctuations and exposure to chemicals, contributing to vehicle safety and performance.

Aerospace Industry: In the aerospace sector, Rubber O-Rings play a pivotal role in hydraulic systems, engines, and fuel lines. Their resilience to extreme conditions is vital for safe and reliable air travel.

Industrial Machinery: O-Rings are indispensable for sealing hydraulic and pneumatic systems in industrial machinery, ensuring smooth and efficient operations in manufacturing plants and factories.

Medical and Pharmaceutical Devices: The medical and pharmaceutical industries rely on Rubber O-Rings to maintain sterile environments in their equipment and devices. O-Rings’ biocompatibility and sterilization resistance make them a trusted choice for patient safety.

Oil and Gas Exploration: O-Rings are critical in the oil and gas industry, sealing valves, pumps, and drilling equipment to prevent leaks and safeguard operations, as well as the environment.

Key Benefits:

Effective Sealing: Rubber O-Rings offer exceptional sealing performance, preventing leaks and contamination.

Resistance to Environmental Factors: They can withstand extreme temperatures, harsh chemicals, and challenging environmental conditions.

Durability: O-Rings have a long service life, reducing maintenance and replacement costs.

Cost-Efficiency: They are a cost-effective sealing solution for various industries.

Versatility: O-Rings are available in various materials and sizes to suit a wide range of applications.

Conclusion: Though unassuming in appearance, Rubber O-Rings are instrumental in modern engineering and play a vital role in ensuring the reliability and safety of equipment and systems across various industries. Incorporating Rubber O-Rings in your projects can significantly enhance the performance and longevity of your machinery, all while safeguarding against leaks and contamination.