Rubber Gaskets: The Silent Guardians of Industrial Excellence

Introduction:

In the intricate and multifaceted landscape of industrial applications, rubber gaskets often work silently behind the scenes, but they are the unsung heroes that ensure excellence in sealing systems. These unassuming components, engineered from elastomeric materials such as neoprene, silicone, EPDM, and nitrile, play a pivotal role in preserving the integrity and efficiency of various processes. In this article, we will unveil the significance of rubber gaskets, explore their diverse applications, and delve into the essential factors to consider when selecting the ideal gasket for your specific needs.

The Quiet Achievers: Rubber Gaskets

Despite their unassuming presence, rubber gaskets are fundamental to industries spanning automotive, aerospace, plumbing, and manufacturing. Their primary role is to establish secure seals, preventing the escape of liquids, gases, or contaminants, thus ensuring safety and process efficiency. With their resilience and resistance to environmental factors, they are the silent guardians of reliability in various applications.

Applications Across Industries:

Automotive Precision: Rubber gaskets are indispensable in the automotive sector, sealing critical components within engines, transmissions, and exhaust systems. They contribute to fuel efficiency, emissions control, and noise reduction.

Plumbing and HVAC Excellence: In plumbing systems, rubber gaskets are commonly found in faucets, valves, and pipe connections to prevent water leakage. In HVAC systems, they create dependable seals in ductwork, enhancing energy efficiency.

Aerospace: Where Precision is Non-Negotiable: The aerospace industry relies on rubber gaskets to seal vital components such as engine parts and aircraft windows. These gaskets must meet stringent performance and safety standards.

Manufacturing Prowess: In manufacturing processes, rubber gaskets are instrumental in sealing pumps, valves, and tanks, ensuring the integrity of chemical and industrial operations.

Selecting the Right Rubber Gasket:

Choosing the appropriate rubber gasket is paramount to achieving a reliable, long-lasting seal. To make an informed decision, consider the following crucial factors:

Material Mastery: Different elastomers are suited for different environments. Evaluate the chemical resistance, temperature tolerance, and durability required for your specific application.

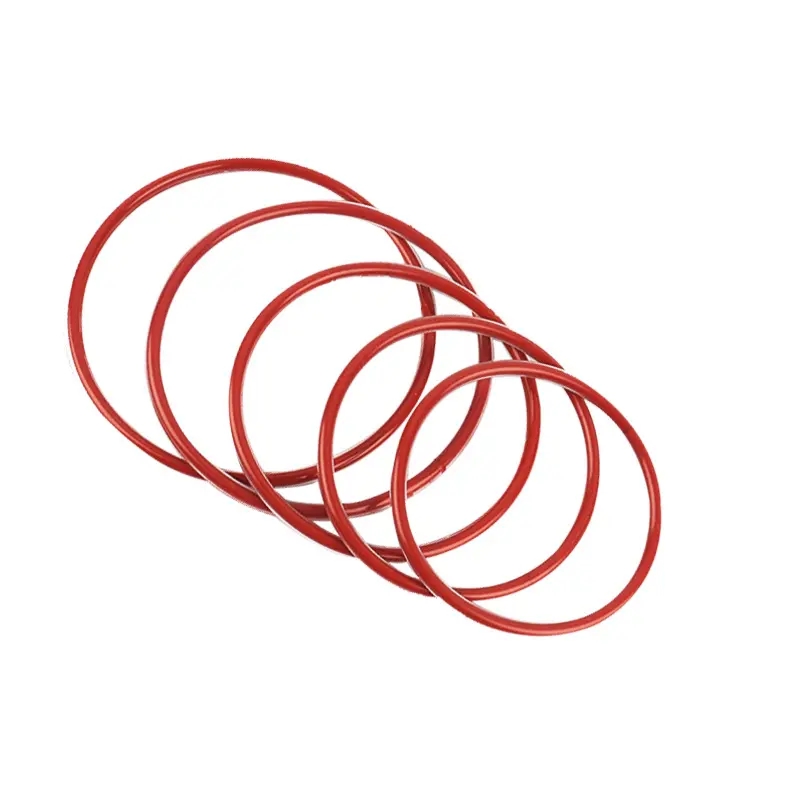

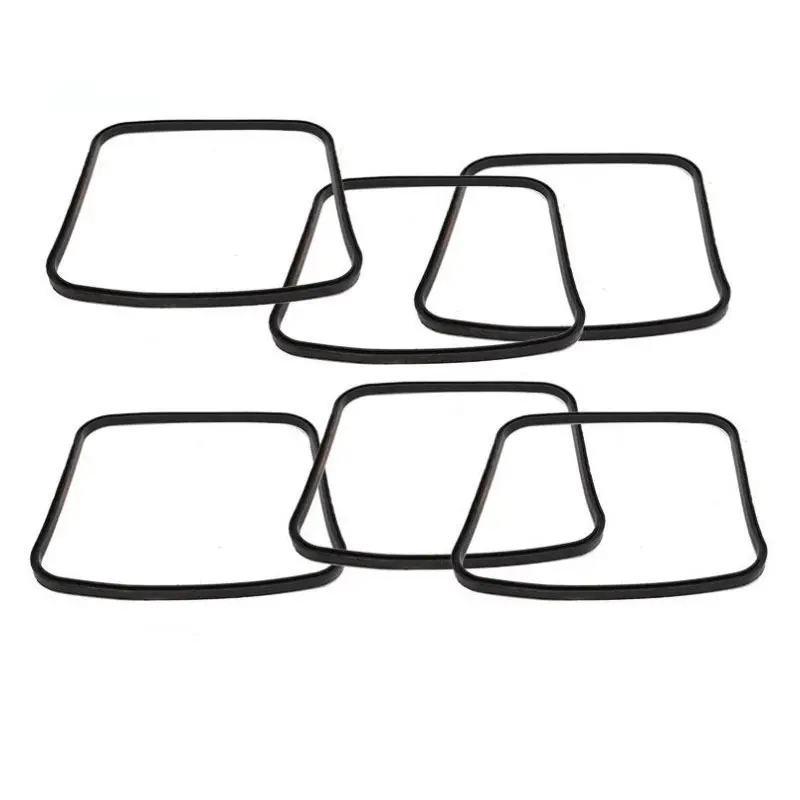

Design Versatility: Rubber gaskets come in various shapes and designs, including O-rings, square-cut gaskets, and flange gaskets. Select the design that best aligns with your sealing requirements.

Pressure and Temperature Parameters: Understand your operating conditions, including pressure and temperature, as these factors significantly influence gasket performance.

Compliance and Certification: Some industries enforce stringent regulations and standards for gasket materials. Ensure that your selected gasket complies with these requirements.

Conclusion:

While rubber gaskets may not always be in the spotlight, they are fundamental components in numerous industries, providing dependable sealing solutions for critical applications. Recognizing their importance, making informed material choices, and addressing the specific requirements of your application are essential steps in achieving a successful and enduring seal. Whether you operate in the automotive, aerospace, plumbing, or manufacturing sector, rubber gaskets are the silent heroes of reliability and safety in your processes. Making an informed selection ensures sealing excellence with these versatile and unassuming components.