Rubber Seal Strips: The Defenders of Precision Sealing

Introduction:

In the world of precision sealing, rubber seal strips are the unsung heroes, quietly ensuring the integrity of seals in various applications. This article delves into the intricate world of rubber seal strips, revealing their versatility and emphasizing their role as defenders of precision sealing in different industries.

Diverse Material Selection:

EPDM, Neoprene, Silicone: Rubber seal strips are available in various materials, each with unique attributes. EPDM excels in weather resistance, neoprene in chemical resistance, and silicone in flexibility and high-temperature tolerance.

Customization for Precision:

Rubber seal strips can be tailored to specific dimensions and shapes, ensuring a perfect fit for windows, doors, machinery, and more.

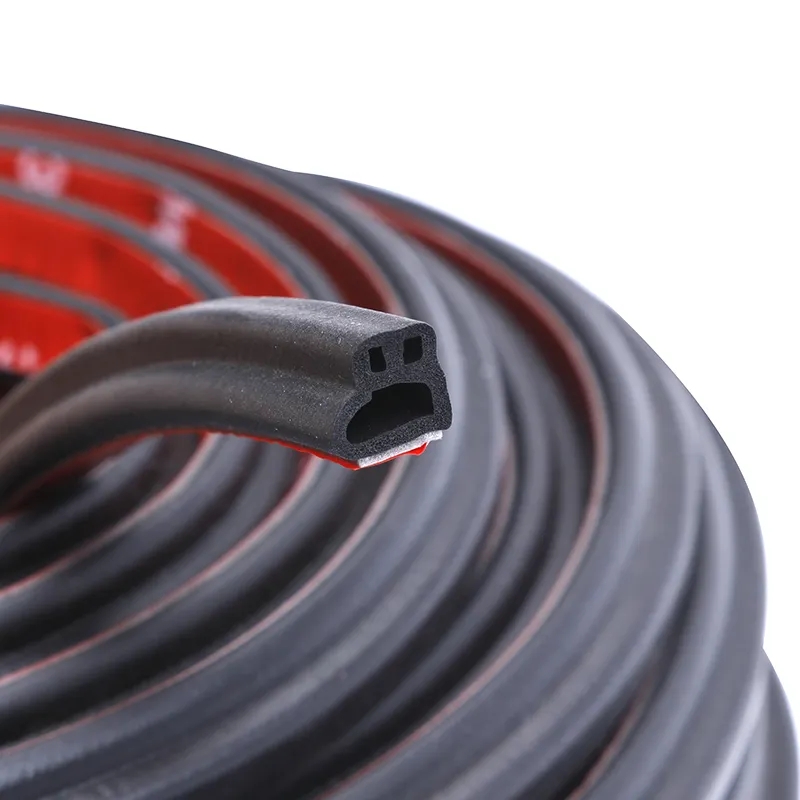

Effortless Installation with Adhesive Backing:

Many rubber seal strips come with adhesive backing, simplifying the installation process, reducing labor time, and making them user-friendly.

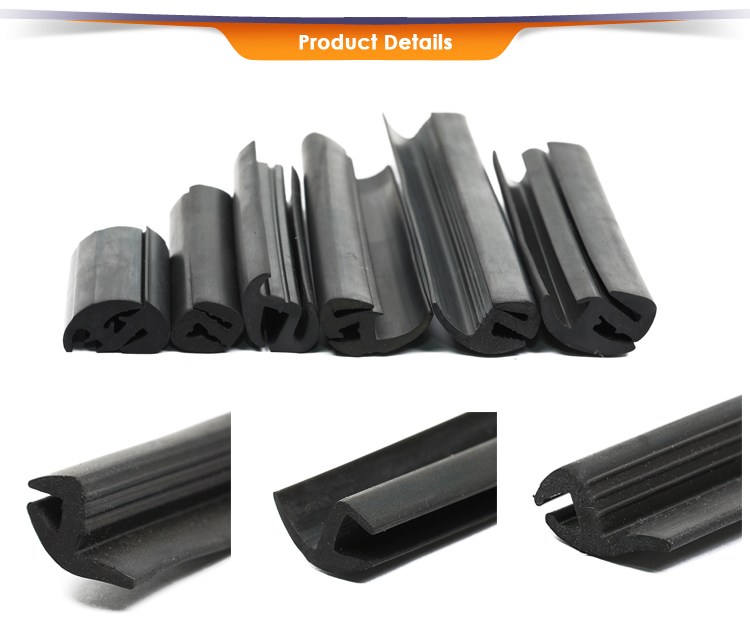

Shapes and Profiles for Varied Needs:

Available in a multitude of shapes, including D-shaped, P-shaped, and more, rubber seal strips cater to diverse sealing requirements across different industries.

Versatile Applications:

Automotive: Rubber seal strips are vital for sealing doors, windows, and hoods, providing noise reduction and effective weatherproofing for vehicles.

Construction: They create watertight and airtight seals in windows and doors, enhancing energy efficiency in buildings, ultimately reducing heating and cooling costs.

Manufacturing: In manufacturing, rubber seal strips reduce vibration and noise in machinery while acting as a barrier against dust and contaminants.

Home Improvement: Homeowners benefit from these strips by sealing gaps around windows and doors, leading to improved insulation and energy savings.

Key Advantages:

Weather Resistance: Rubber seal strips effectively keep out rain, wind, and other harsh elements, ensuring that interiors remain protected in all weather conditions.

Noise Reduction: They provide acoustic insulation, creating quieter and more comfortable indoor environments, improving the quality of life in both residential and industrial settings.

Energy Efficiency: By sealing gaps and preventing air leakage, rubber seal strips contribute to energy efficiency by reducing heating and cooling costs, ultimately saving money and reducing environmental impact.

Dust and Insect Barrier: These strips create a protective barrier against dust, pollutants, and insects, ensuring a clean and hygienic environment.

Vibration Dampening: Rubber seals absorb and dampen vibrations, increasing the longevity of machinery and improving overall performance.

Conclusion:

In conclusion, rubber seal strips are the defenders of precision sealing, addressing intricate sealing needs in various industries. Their adaptability, ease of installation, and durability make them a preferred choice for professionals and do-it-yourself enthusiasts alike. Investing in high-quality rubber seal strips ensures effective sealing, protection, and insulation, making them an indispensable component in countless projects.