Introduction:

In the intricate world of engineering and machinery, there exists a hidden hero, the Rubber Oil Seal. These unassuming rings have a significant impact on the functionality and longevity of various mechanical systems. Renowned for their sealing precision, adaptability, and durability, Rubber Oil Seals are vital components that ensure the seamless operation of countless machines and engines. This article delves into the world of Rubber Oil Seals, exploring their unique characteristics, practical advantages, and the diverse applications that have solidified their status as indispensable components for professionals and industries worldwide.

Rubber Oil Seals: Guardians of Fluid Integrity

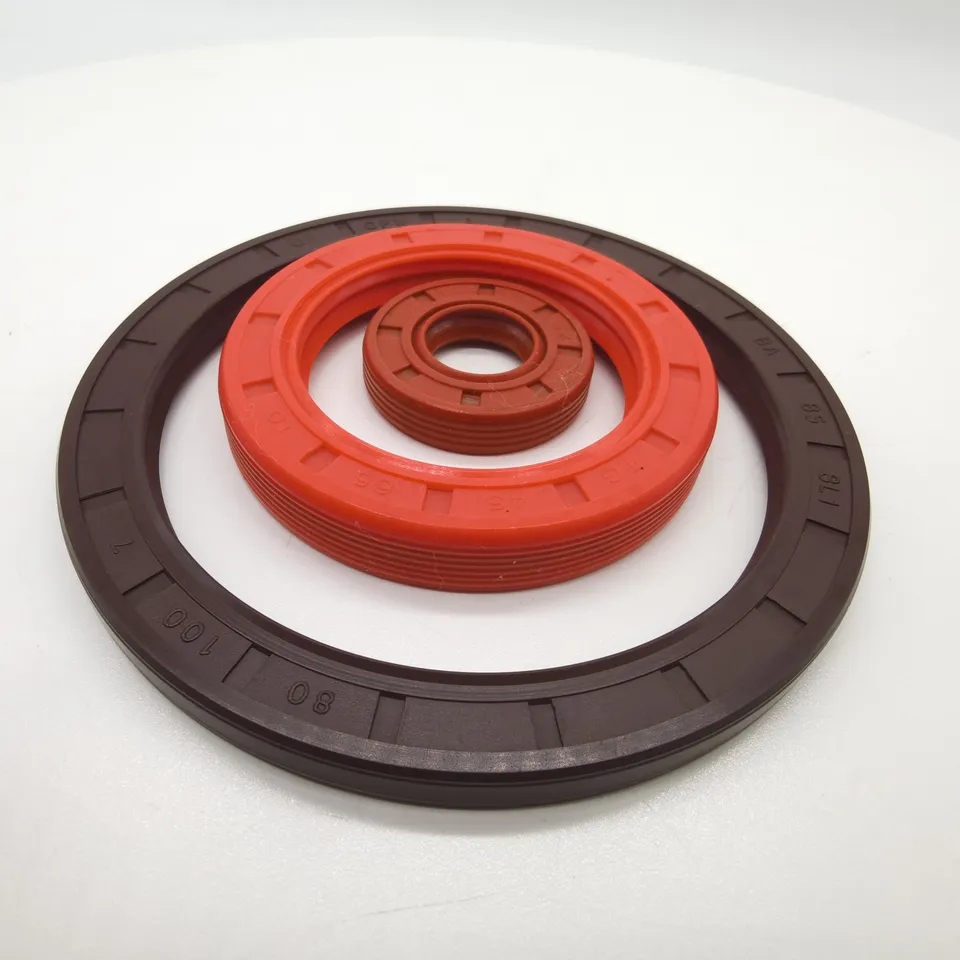

Rubber Oil Seals, also known as oil seals or shaft seals, are circular elastomeric rings typically made from high-quality rubber compounds. They are meticulously designed to fit around the shafts of rotating equipment, forming a barrier that prevents the escape of lubricants and the ingress of contaminants.

Advantages of Rubber Oil Seals:

Precise Sealing: Rubber Oil Seals are engineered for precision, creating a reliable barrier against the escape of oils, greases, and other fluids. This precision ensures smooth and efficient machinery operation.

Versatility: These seals are available in various sizes, materials, and designs, making them adaptable to a wide range of applications, from automotive engines to industrial machinery.

Longevity: Rubber Oil Seals are designed to withstand the rigors of continuous use, offering extended service life and reduced maintenance costs.

Resistance to Contaminants: They provide protection against the intrusion of dirt, dust, and moisture, which can lead to component wear and failure.

Temperature Tolerance: These seals can function effectively in a wide range of temperatures, making them suitable for both hot and cold operating environments.

Chemical Compatibility: Rubber Oil Seals can be customized to resist specific chemicals, ensuring compatibility with various fluids used in machinery.

Applications of Rubber Oil Seals:

Automotive Industry: Rubber Oil Seals are vital components in vehicle engines, transmissions, and axles, preventing lubricant leakage and ensuring optimal performance.

Industrial Machinery: They play a critical role in industrial equipment, including pumps, gearboxes, and compressors, where maintaining fluid integrity is essential.

Agricultural Equipment: Rubber Oil Seals are used in farm machinery to protect bearings and moving parts from harsh outdoor conditions.

Construction Equipment: These seals ensure the reliability of heavy machinery, such as bulldozers and excavators, in rugged work environments.

Aerospace: In the aerospace sector, they are used in engines and mechanical systems, guaranteeing the integrity of critical components.

In Conclusion:

Rubber Oil Seals, often overlooked but essential, are the epitome of precision sealing, ensuring the integrity and reliability of various mechanical systems. Their unique attributes, encompassing precise sealing, durability, and resistance to contaminants, have made them the preferred choice for professionals and industries worldwide. Whether you are involved in automotive engineering, industrial machinery, or aerospace applications, Rubber Oil Seals offer the precision and performance required to keep your machinery operating at peak efficiency. Explore the world of Rubber Oil Seals and discover their enduring value, ensuring the success of your projects, no matter the industry or application.