Introduction:

In the intricate world of industry and engineering, where precision and reliability are paramount, one often-overlooked component quietly plays a pivotal role – the Rubber Gasket. These seemingly unremarkable rings have an essential function in sealing gaps, preventing leaks, and maintaining the integrity of equipment and systems. Rubber Gaskets have emerged as indispensable components for a wide range of applications, from automotive to manufacturing. This article delves into the world of Rubber Gaskets, exploring their unique attributes, practical advantages, and the diverse applications that make them trusted assets for professionals and industries worldwide.

Rubber Gaskets: The Unsung Guardians of Sealing

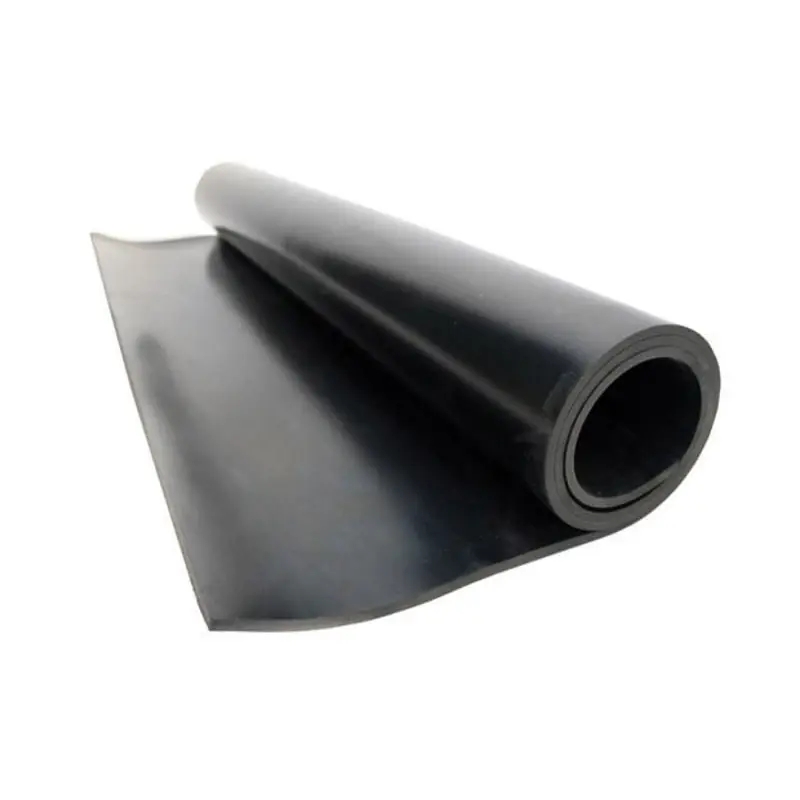

Rubber Gaskets are sealing components made from various rubber materials, each chosen for its suitability in specific applications. They are designed to fit between two surfaces, creating a secure seal that prevents the escape of fluids, gases, or contaminants.

Advantages of Rubber Gaskets:

Impeccable Sealing: Rubber Gaskets provide a reliable sealing solution, ensuring no medium can penetrate or escape through gaps. Their flexibility and adaptability make them suitable for a wide range of applications.

Versatility: Available in various shapes, sizes, and materials, Rubber Gaskets are highly versatile and can be customized to meet the unique requirements of different industries.

Durability: Rubber Gaskets are renowned for their durability, capable of withstanding harsh conditions, thus extending the service life of equipment and reducing maintenance costs.

Environmental Resilience: Rubber Gaskets exhibit excellent resistance to temperature variations, chemicals, and environmental factors, making them ideal for a variety of applications.

Energy Efficiency: By creating a perfect seal, Rubber Gaskets contribute to energy conservation and reduced operational costs, a valuable asset in industries where efficiency is critical.

Applications of Rubber Gaskets:

Automotive Industry: Rubber Gaskets are used in engines, transmissions, and doors to ensure airtight seals, preventing leaks and maintaining vehicle performance.

Construction Sector: In construction, they are instrumental in sealing doors and windows, enhancing insulation, weatherproofing, and energy efficiency.

Industrial Machinery: Rubber Gaskets are indispensable for heavy machinery and equipment, preventing fluid leaks and maintaining safety standards.

Aerospace: In the aerospace industry, Rubber Gaskets play a crucial role in sealing critical components, maintaining pressure differentials, and preventing leaks in aircraft systems.

Food and Pharmaceutical Industry: These gaskets are essential for maintaining hygienic seals in containers and equipment, preventing contamination in food and pharmaceutical production.

In Conclusion:

Rubber Gaskets are the unsung heroes that ensure precision and reliability in numerous industries. Their versatility, durability, and resistance to environmental factors have made them the preferred choice for professionals and industries seeking dependable sealing solutions. Whether you are involved in automotive engineering, construction, industrial machinery, or aerospace applications, Rubber Gaskets offer the reliability and performance needed to guarantee safety, efficiency, and productivity. Explore the world of Rubber Gaskets and discover their enduring value, securing the success of your projects, regardless of the industry or application.